Rather than replacing proven process improvement frameworks like Kaizen, Lean, and Six Sigma, AI-powered solutions augment them by automating labor-intensive analysis and enabling continuous, data-driven improvement.

Traditional process improvement methodologies remain relevant, but modern markets move faster than periodic improvement cycles can accommodate.

42% of CEOs say their companies have started competing in new services and sectors over the last five years, and this steady pace of innovation is one of the few things keeping them confident about revenue growth. Timelines are also getting stricter, with all global CEOs reporting that they spend almost 47% of their time on projects with a one-year time horizon.

In 2026, 30% of organizations are already redesigning their processes around AI projects, and 37% are using AI at the surface level, planning on embedding it into their core processes. AI can help businesses accelerate their development strategies, with less pressure on employees and greater certainty about the future.

This guide compares traditional process improvement with AI-augmented approaches, examines how process mining, task mining, and predictive analytics accelerate results, and provides real-world outcomes from manufacturing and insurance implementations.

How do you get more from your existing improvement programs without starting over?

Temidayo Daodu, an Innovative Executive driving operational excellence across enterprises, shares her perception of the questions that business leaders face when aiming at optimizing their business processes:

Business Process Improvement is a structured approach to analyzing, improving, and optimizing business processes. The questions BPI poses are:

- Effectiveness: Are we actually delivering what the customer needs?

- Efficiency: Are we doing it without wasting resources?

- Adaptability: Can we pivot when the market shifts?

- Safety: Are we managing risk and environmental impact?

This interpretation of BPI meaning helps organizations focus on what truly drives day-to-day performance. While revenue remains critical, long-term operational effectiveness depends on delivering customer value, reducing waste and risk, and maintaining the ability to adapt as market conditions evolve. By addressing these fundamentals, business process improvement efforts lead to more sustainable operational excellence.

Why traditional methods hit limits at enterprise scale

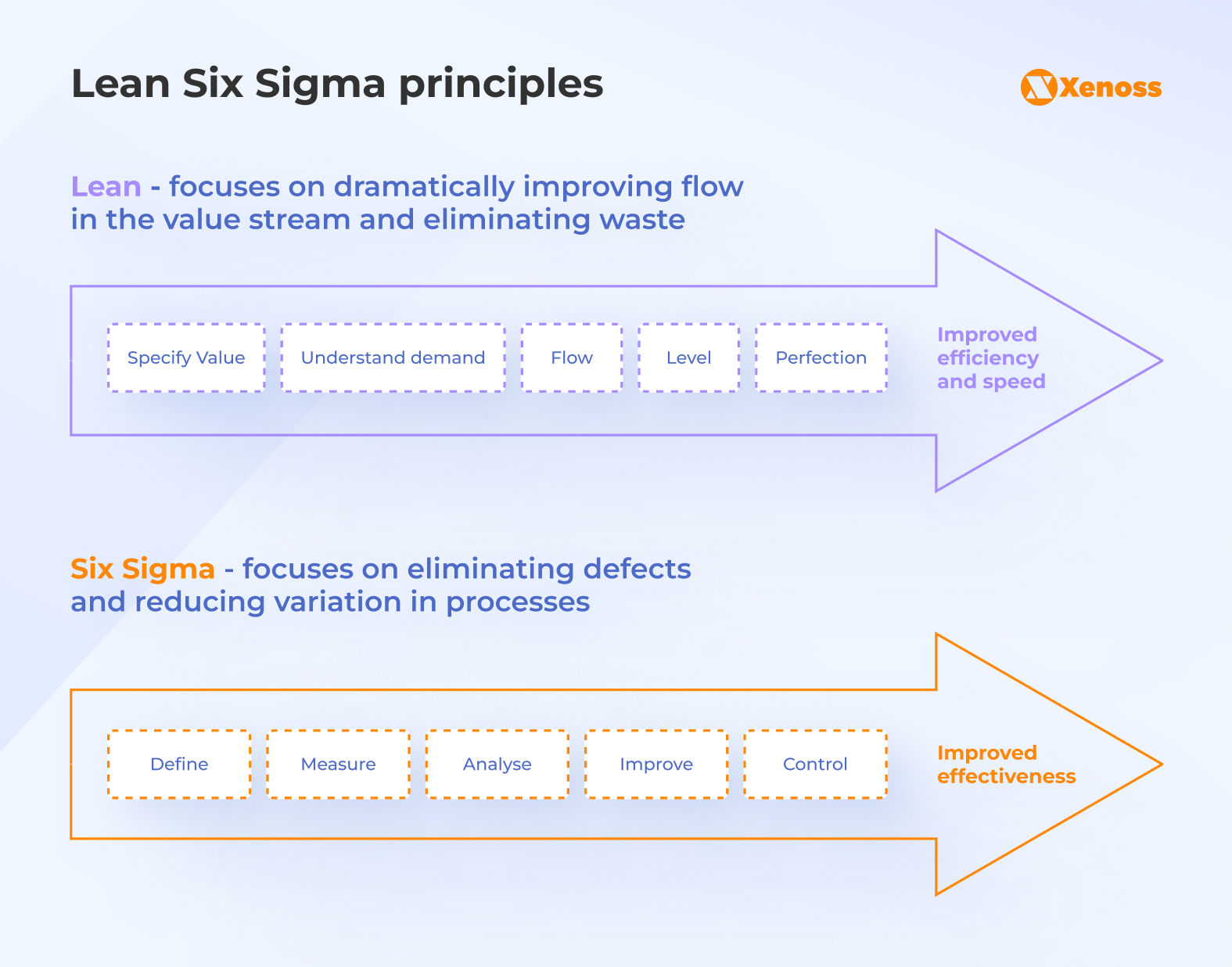

Kaizen, Lean, and Six Sigma have delivered decades of documented results. Kaizen builds continuous improvement into daily operations. Six Sigma applies statistical rigor through the DMAIC framework (Define, Measure, Analyze, Improve, Control). Lean eliminates waste and optimizes flow. Most mature organizations combine all three.

As Jeffrey K. Liker wrote in “The Toyota Way”: “Most business processes are 90% waste and 10% value-added work.” The goal of modern process improvement is to flip this dynamic and maximize the share of value-adding work.

The frameworks work. Scaling them across global operations, multiple systems, and thousands of process variations is where teams struggle.

Sampling vs. complete visibility. Traditional process analysis relies on observation and sampling. A Six Sigma project might analyze hundreds of transactions to identify patterns. Process mining analyzes millions, capturing every variant, every exception, every path the documented process doesn’t account for.

Periodic projects vs. continuous monitoring. DMAIC projects run in cycles. The Define and Measure phases alone typically require 4-6 weeks of data collection. By the time improvements roll out, conditions have shifted. AI-enabled systems flag deviations in real time.

Manual root cause analysis vs. pattern detection. Human analysts test hypotheses one at a time. AI simultaneously correlates thousands of variables, surfacing root causes that manual analysis would take months to uncover.

AI removes these constraints. The methodology stays. The speed and accuracy improve.

How AI transforms process improvement

AI-powered process improvement platforms combine process mining (analyzing system event logs), task mining (recording user interactions), and predictive analytics to provide real-time visibility into every process, bottleneck, and optimization opportunity.

Process mining: Complete visibility into workflow variations

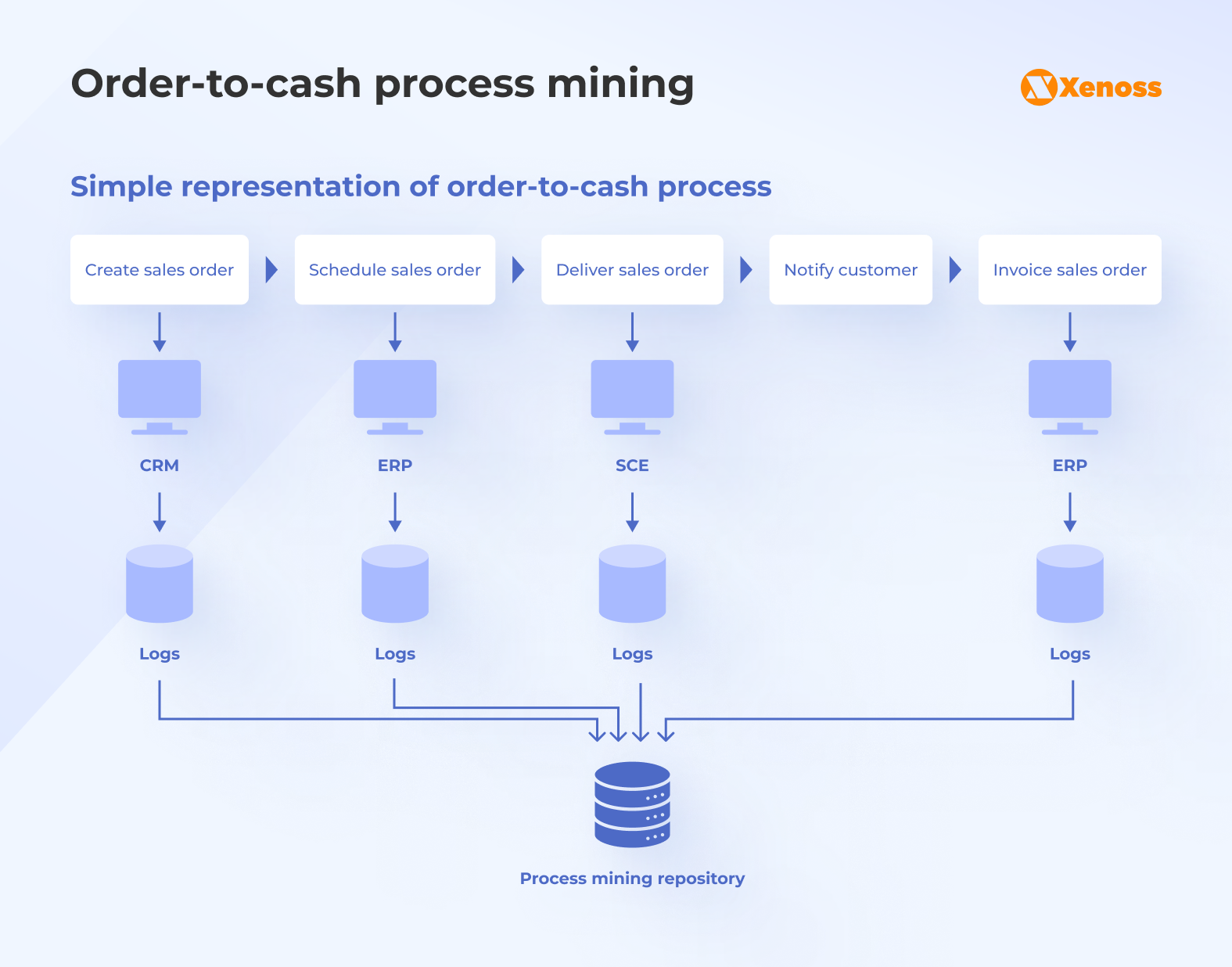

Process mining involves extracting event logs from core operational systems (e.g., ERPs, CRMs) to define end-to-end business workflows and identify potential bottlenecks that reduce process efficiency.

Businesses are increasingly using diverse AI/ML technologies, including anomaly detection models, natural language processing (NLP), large language models (LLMs), and digital twins, to accelerate process mining. Hyperautomation is also commonly used to shift from traditional diagnostic analytics to descriptive and predictive analytics.

Example: With an automated order-to-cash process, Siemens reduced rework by 11% globally and increased automation rate by 24%, eliminating 10 million manual touches per year.

Discover also how AI enhances the procurement process in the manufacturing industry.

Task mining: Understanding human workflow patterns

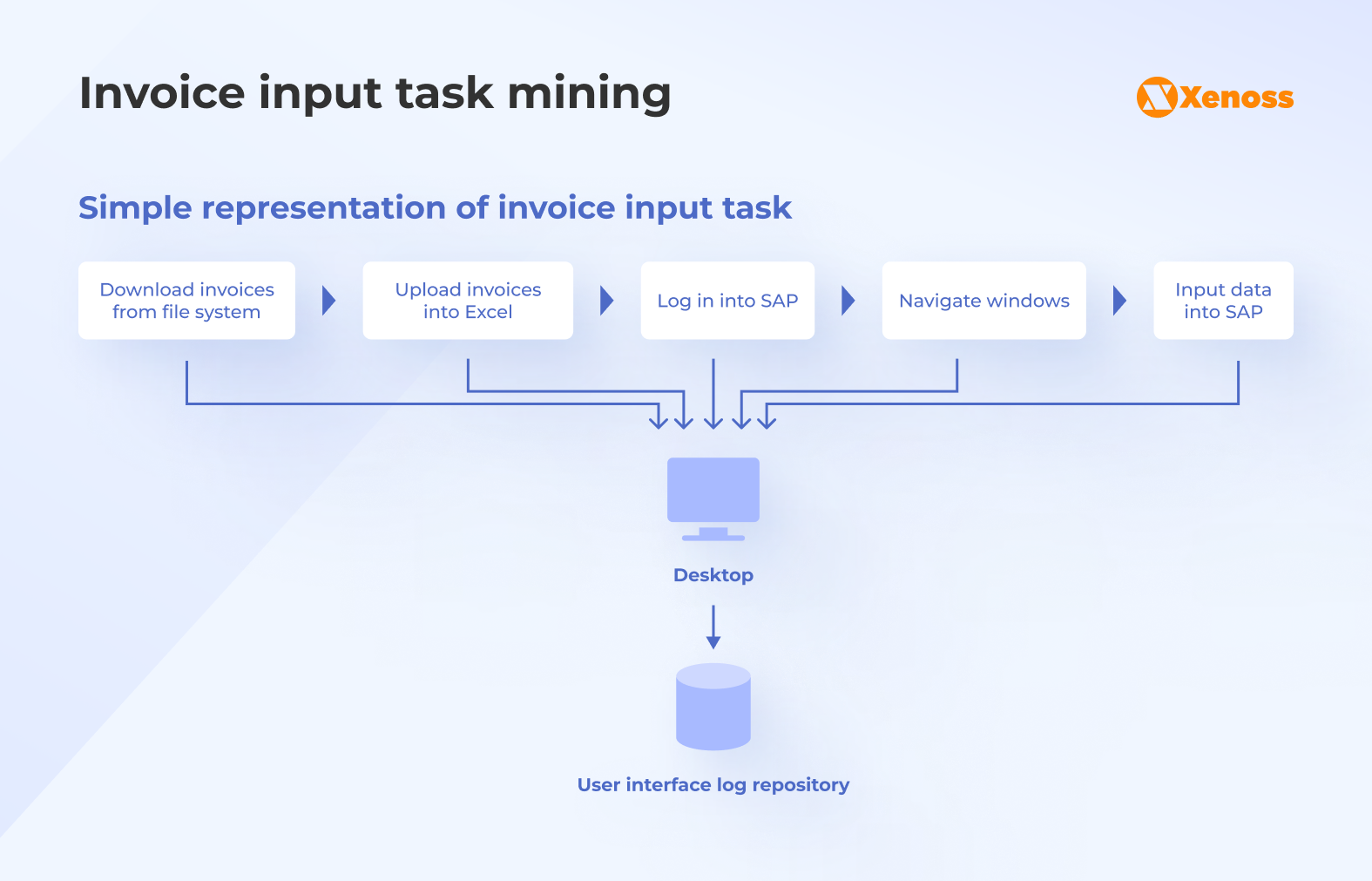

Task mining operates at a more granular level than process mining, gathering application interaction data to define how efficiently employees handle specific actions and steps, and how many workarounds they need to complete a task.

NLP, optical character recognition (OCR), robotic process automation (RPA), and computer vision are applied for tracing steps and actions in a particular task.

Task mining is critical in environments where:

- Large portions of work happen outside core systems

- Employees rely on spreadsheets, email, or legacy tools

- Manual interventions explain why automation or optimization stalls

Task mining helps organizations understand where human effort is concentrated, which steps are unnecessarily manual, and which tasks introduce variation, delays, or error risk.

Example: A logistics provider automated input of over 4,000 invoices per month, improving processing speed by 5 times and removing repetitive data-entry steps by integrating AI invoice extraction with Cargowise and Getex workflows.

When combined, task and process mining provide a helicopter view of business operations, connecting macro-level process flows with micro-level human execution.

Process mining vs. task mining: When to use each

| Criterion | Process mining | Task mining |

|---|---|---|

| What it analyzes | End-to-end business processes across systems | Individual user actions at the desktop or application level |

| Primary data source | System event logs (ERP, CRM, BPM, ticketing systems) | User interaction data (clicks, keystrokes, screen activity) |

| Level of visibility | Process and workflow level | Task and activity level |

| Typical questions answered | “How does the process flow across systems?” | “How do people perform the work inside applications?” |

| Main strengths | Reveals bottlenecks, variants, rework loops, and compliance gaps across the process | Exposes manual effort, workarounds, inefficiencies, and non-standard task execution |

| Typical use cases | Process optimization, compliance analysis, SLA monitoring, and end-to-end cycle time reduction | Automation discovery, productivity analysis, and task standardization |

| Best suited for | Structured, system-driven processes with digital footprints | Knowledge work, manual tasks, and activities outside core systems |

| Limitations | Limited visibility into work done outside systems or between steps | Lacks end-to-end process context on its own |

| Role in the continuous improvement cycle | Identifies where processes break down or deviate | Explains why work is slow, inconsistent, or manual |

| Typical output | Process maps, variants, KPIs, bottleneck analysis | Task flows, time spent per action, automation candidates |

| How AI enhances it | Predictive bottleneck detection, anomaly detection, root-cause analysis | Intelligent pattern recognition, task clustering, automation recommendations |

Predictive analytics for process improvement

Traditional process excellence relies on historical analysis, which means understanding what went wrong after it has already happened. Predictive process analytics advances this model by using AI to anticipate bottlenecks, delays, and failures before they affect operations or customers (e.g., predictive maintenance in manufacturing).

By applying predictive ML and AI models to process and task data, organizations can:

- Predict SLA breaches and workload spikes

- Identify early signals of process degradation

- Simulate the impact of process changes before implementation

Example: A healthcare provider combined predictive analytics (by using a multiple linear regression (MLR) model) with operational improvements to predict patient wait times and optimize consultation efficiency. As a result, wait time decreased by 15%, and doctor consultation time decreased by 25%. Appointment processing times improved by 10–15%, leading to an average reduction of 22.5 minutes.

AI process improvement: Quantified outcomes

The table below illustrates the average positive outcomes of the AI-powered process improvement across different industries.

| Performance metric | Traditional process improvement | AI-driven process improvement | Improvement factor | Primary industries measured |

|---|---|---|---|---|

| Bottleneck detection time (days) | 37.0 | 2.1 | 17.6x faster | Manufacturing, financial services |

| False positive rate (%) | 17.2 | 1.7 | 10.1x reduction | Financial services, healthcare |

| Process anomaly detection rate (%) | 76.3 | 97.4 | 1.3x increase | Manufacturing, telecommunications |

| Process cycle time reduction (%) | 18.7 | 43.7 | 2.3x improvement | Supply chain, financial services |

| Resource utilization improvement (%) | 16.4 | 37.2 | 2.3x improvement | Healthcare, manufacturing |

Process improvement results: Manufacturing and insurance case studies

In this section, we’ll provide an overview of how real-life companies in the manufacturing and insurance sectors benefit from AI adoption to improve their core business operations.

Case study: AI-powered lean manufacturing audit

Business case

To achieve operational excellence in manufacturing, 5S audits (Sort, Set in order, Shine, Standardize, Sustain) are a core lean mechanism that maintain workplace discipline and prevent quality and safety issues. However, traditional 5S auditing is often labor-intensive, periodic, and subjective, relying on human auditors whose judgment can vary and typically cannot sustain high-frequency monitoring at scale.

Solution

Therefore, a research team developed an AI-powered 5S audit system based on multimodal large language models (LLMs) and intelligent image analysis and tested it in real manufacturing environments. AI systems automate critical tasks such as visual perception and pattern recognition, and support basic decision-making. Additional integration with industrial IoT systems facilitated the auditing process by providing real-time data from physical devices.

Results

The AI-enabled system sped up the audit process by 50% and reduced operating costs by 99.8% when compared to manual auditing. The system analyzed 75 images captured over a week on the shop floor in 1.3 hours, compared to a manual audit that took 75 hours (1 hour per audit). The projected ROI for the first year of operations is 60.1%; in five years, it’s forecasted to reach 339.6%.

| Method | Cost per audit ($) | Time per audit | Audit frequency (per month) | Staff required |

|---|---|---|---|---|

| Manual | 15.00 | 1 hour | ~20 | 1 auditor |

| AI-automated | 0.03 | 20 minutes | 20+ (scalable) | None |

| Absolute reduction | 74.83 | 40 minutes | Unlimited | 1 person |

| Percentage reduction | 99.8% | 67% | No limit | 100% |

Case study: Insurance claims processing automation

Business case

With an increasing number of insurance claims (1.4 million annually), manual processing became a bottleneck for If P&C Insurance, hindering scalability and overall business performance. Identifying claim parts in the insurance domain requires extensive human expertise and is a time-consuming, knowledge-intensive process.

Solution

The company opted for object-centric process mining powered by AI to optimize claim part processing. They decided on a phased approach that included thorough testing and AI model evaluations, while maintaining a human-in-the-loop to ensure high service quality and trustworthiness. Claims process improvement was one of the strategic objectives of their digital transformation roadmap.

Results

When comparing AI-identified and human-identified claim parts, results showed a 1,420% increase in throughput thanks to AI implementation. Importantly, this gain was achieved without sacrificing interpretability or control, as domain specialists continuously reviewed and validated AI-generated classifications.

Beyond raw throughput, the AI-enabled object-centric process mining approach delivered broader process improvement benefits. By automatically correlating multiple business objects (claims, documents, messages, and process events), the system exposed hidden process bottlenecks that were previously difficult to detect using traditional, case-centric process analysis. This allowed process owners to shift from isolated, manual investigations to system-level, data-driven optimization.

Key takeaway: Even though these AI-powered process improvement solutions have proven efficient, for cross-company implementation and scale, they still require strategic change management, robust security controls, and standardized human-AI collaboration processes.

Bottom line

To succeed with AI in process improvement, organizations need to implement it as an acceleration layer on top of existing process management practices. Established frameworks such as Lean and Six Sigma provide the structure, governance, and decision discipline that AI needs to operate effectively. For example, Lean Six Sigma principles can be used to define quality thresholds, control points, and training signals for AI models.

A pragmatic starting point is AI-enabled process and task mining. These tools help teams observe how people perform their work across systems and tools, reveal hidden bottlenecks, and quantify inefficiencies that are difficult to detect through workshops or manual analysis.

From there, organizations should focus on a small number of high-impact processes, use AI to speed up analysis and feedback cycles, and keep final decisions in the hands of process owners. This creates clear proof of value by allowing teams to compare baseline performance gaps with AI-augmented execution before scaling further.

The Xenoss team knows how to select the right AI technology and continuous improvement software for your unique processes and tasks to deliver measurable ROI, increased productivity, and, ultimately, operational excellence.