Hyperautomation is the hottest term in the CIO dictionary, and a market worth over $50 billion.

Companies are looking for ways to combine the capabilities of robotic process automation, AI agents, and even old-school deterministic systems to, as IBM puts it, ‘automate everything that can be automated. ’

For many executives, mastering hyperautomation is now a top-of-the-mind concern.

Gartner data claims hyperautomation is a priority for 90% of large enterprises and predicts that companies will automate 30% of their processes by the end of 2026.

By now, the frontrunners are seeing drastic bottom-line improvements – saved working hours, improved outputs, and increased customer satisfaction. But, besides these successes, there are many failed, discontinued, or under-performing hyperautomation pilots.

In this blog post, we will look deeper into the fundamental concepts high-performing adopters got right and the pitfalls that failed promising projects, so that CIOs can maximize the odds of success.

Before that, let’s go over the basics.

What makes hyperautomation different from old-school automation

The key difference between the two is scope.

A standard approach to automation is “one task, one technology”, for example, an enterprise company automating document digitization with an OCR tool.

Hyperautomation, on the other hand, targets complex processes (that are made of multiple connected tasks) and uses several technologies.

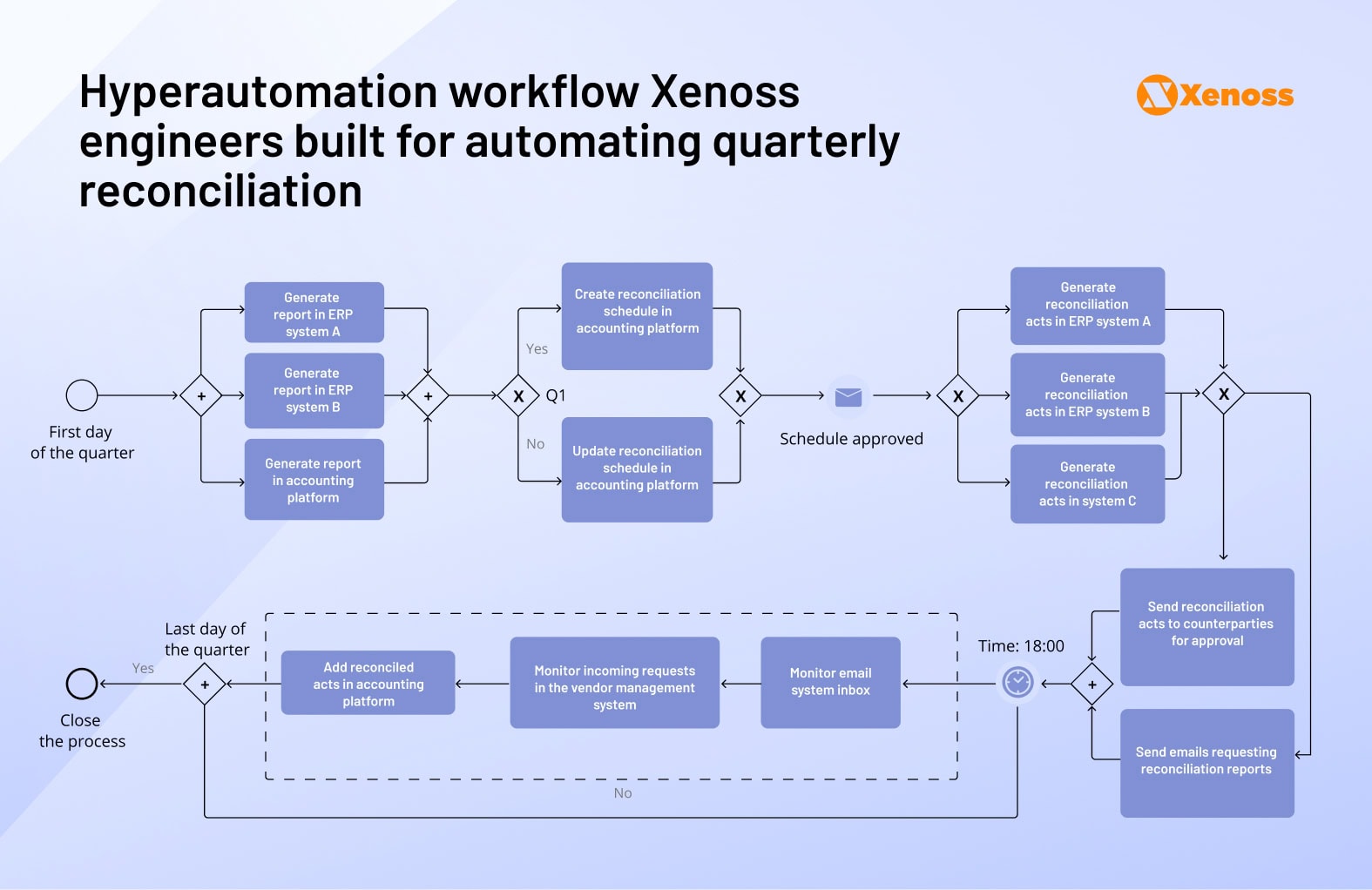

Xenoss engineers helping a global retailer create an autonomous invoice management workflow is an example of hyperautomation.

Tasks we automated:

- Monitoring and approval of incoming vendor requests

- Creating reconciliation acts

- Filing discrepancy reports in the ERP

Technologies we used:

- Deterministic automation for basic reporting and filling in pre-compiled reconciliation acts

- A multi-agent platform for complex operations like building a reconciliation schedule and detecting reports that need human approval.

Because the complexity and scale are higher for hyperautomation projects, so are the returns. In our case, the reconciliation automation solution cut the time per account by 5-6 times, from thirty to about five minutes.

Which technologies power hyperautomation projects?

Hyperautomation mostly owes its rapid growth to the explosion of generative AI tools and, as of late, AI agents. Self-learning, adaptable, and ‘reasoning’ technologies became a missing piece connecting other technologies companies were already using to streamline single tasks.

Here’s how the core technologies work together:

- Robotic process automation handles the execution layer by mimicking human software interactions. Traditional RPA followed rigid, predetermined sequences. Modern AI-enhanced RPA adapts to data variations, learns from exceptions, and optimizes task sequences over time – making it reliable enough for complex, multi-step processes.

- No-code and low-code platforms democratize automation development, allowing business users to build workflows without engineering bottlenecks. GenAI-powered platforms now generate automation logic from natural language descriptions, dramatically reducing the time from concept to working pilot.

- Advanced analytics provides the intelligence layer that transforms reactive automation into proactive optimization. Real-time monitoring identifies bottlenecks, predictive analytics anticipates process failures, and prescriptive insights recommend workflow improvements – creating continuous performance enhancement.

- Internet of Things serves as the sensory network feeding real-world data into digital workflows. Equipment sensors trigger maintenance automations, customer interaction data guides service responses, and environmental monitors adjust operational parameters – bridging physical and digital process automation.

The biggest improvement of hyperautomation upon traditional workflow automation is that it lets companies freely combine technologies into a single system, managed by intelligent agents with minimal human involvement.

Where traditional automation had the limitations of scalability and often would drive only incremental improvements, a broader scope of hyperautomation empowers it to deliver organization-wide impact.

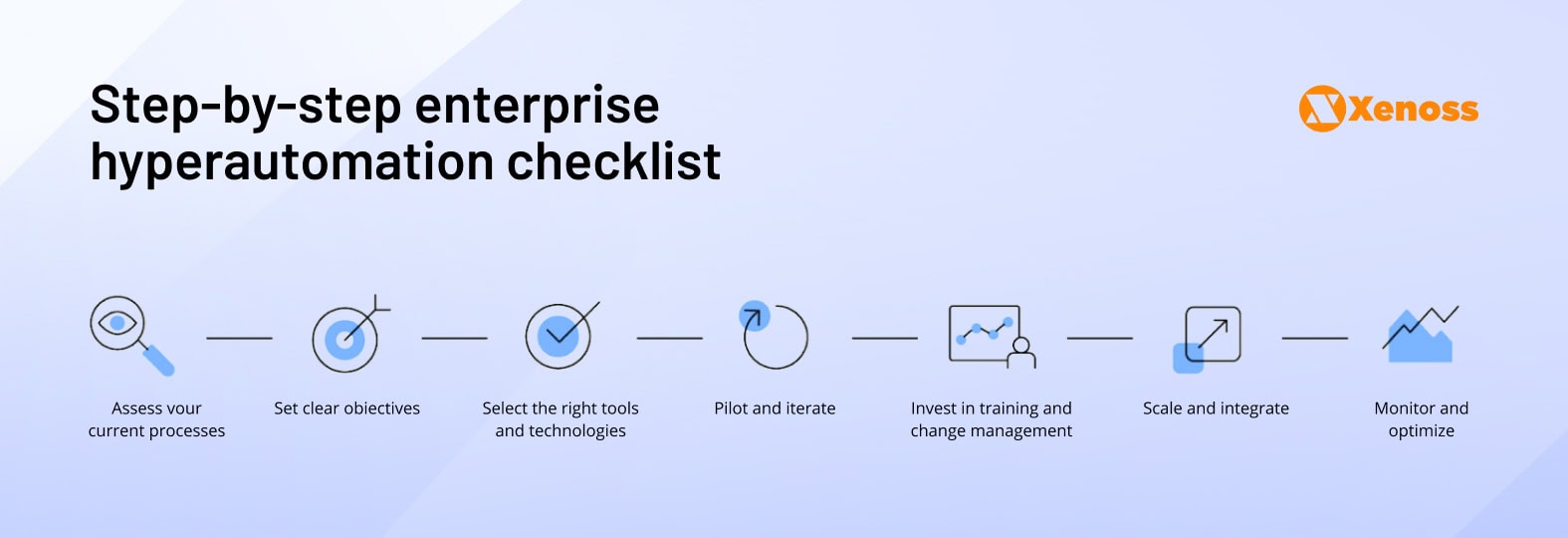

Enterprise hyperautomation checklist

Every enterprise will inevitably have a personalized hyperautomation playbook that depends on organizational needs at that time and the company’s growth roadmap.

But years of helping organizations automate complex workflows have repeatedly convinced Xenoss engineers that there’s a standardized hyperautomation process that tends to outperform other alternatives.

This seven-step sequence is effective for companies across multiple industries and different levels of prior hyperautomation experience.

- Start by selecting automation-friendly processes.

First, create a high-level process map for your organization. Then, document each one in detail and note those that require a lot of manual effort, are error-prone, or often create bottlenecks in other business areas.

Look for processes with these characteristics: high volume and repetitive tasks, clear rules and decision points, minimal exceptions requiring human judgment, and measurable outcomes that demonstrate ROI.

- Identify hyperautomation goals.

Be very specific about the goals your organization aims to reach with hyperautomation. By how much would you like to reduce processing time? How many working hours should teams save? How much do you expect successful hyperautomation to reduce the total cost of ownership?

Identify these metrics before you start and measure them from the beginning, iterating as you move forward. Common success metrics include process cycle time reduction, error rate improvements, cost per transaction, and employee satisfaction scores.

- Build a hyperautomation stack.

Identify the technologies and specific tools that would enable successful hyperautomation. Have clear vendor selection criteria to make sure no incompatibilities or high licensing costs catch your team by surprise.

Consider integration capabilities, scalability requirements, security compliance, and total cost of ownership, including implementation, training, and maintenance expenses.

- Start with a small-scale pilot, then expand.

Test the automation at the scale of a single team before rolling it out organization-wide. Smaller pilot tests are easier to monitor and refine, and less straining on the company’s talent and financials.

Choose a pilot process that’s representative of broader organizational challenges but contained enough to manage effectively. Success here builds credibility for larger initiatives.

- Have a clear distribution strategy.

Plan how hyperautomation will expand to departments beyond the pilot team. Enterprise companies tend to see high automation success by setting up small hyperautomation units for each regional department or business role.

Consider creating centers of excellence that can provide guidance, share best practices, and maintain standards across different implementation teams.

- Monitor continuously.

Set a review and iteration schedule for your hyperautomation project. At review meetings, examine if automations are meeting ROI milestones, whether they create new bottlenecks (like time-consuming maintenance or high infrastructure costs), and how each automated workflow can be further optimized.

Track both quantitative metrics and qualitative feedback from users to identify improvement opportunities and potential expansion areas.

7. Plan for change management

Address the human side of hyperautomation early. Communicate transparently about how automation will affect roles, provide retraining opportunities for displaced tasks, and involve employees in identifying automation opportunities.

Successful hyperautomation requires buy-in from the people whose work it affects most directly.

This hyperautomation blueprint is a helpful starting point to help leaders build an implementation roadmap. But turning hyperautomation into a game-changer often requires going beyond set-in-stone playbooks and making creative and bold decisions – as seen in four successful case studies we will now look at.

How to win at hyperautomation? Four lessons from successful pilots

To have an actionable playbook on making the most of hyperautomation, let’s examine real-world case studies of enterprise companies successfully streamlining processes in finance, healthcare, retail, and manufacturing.

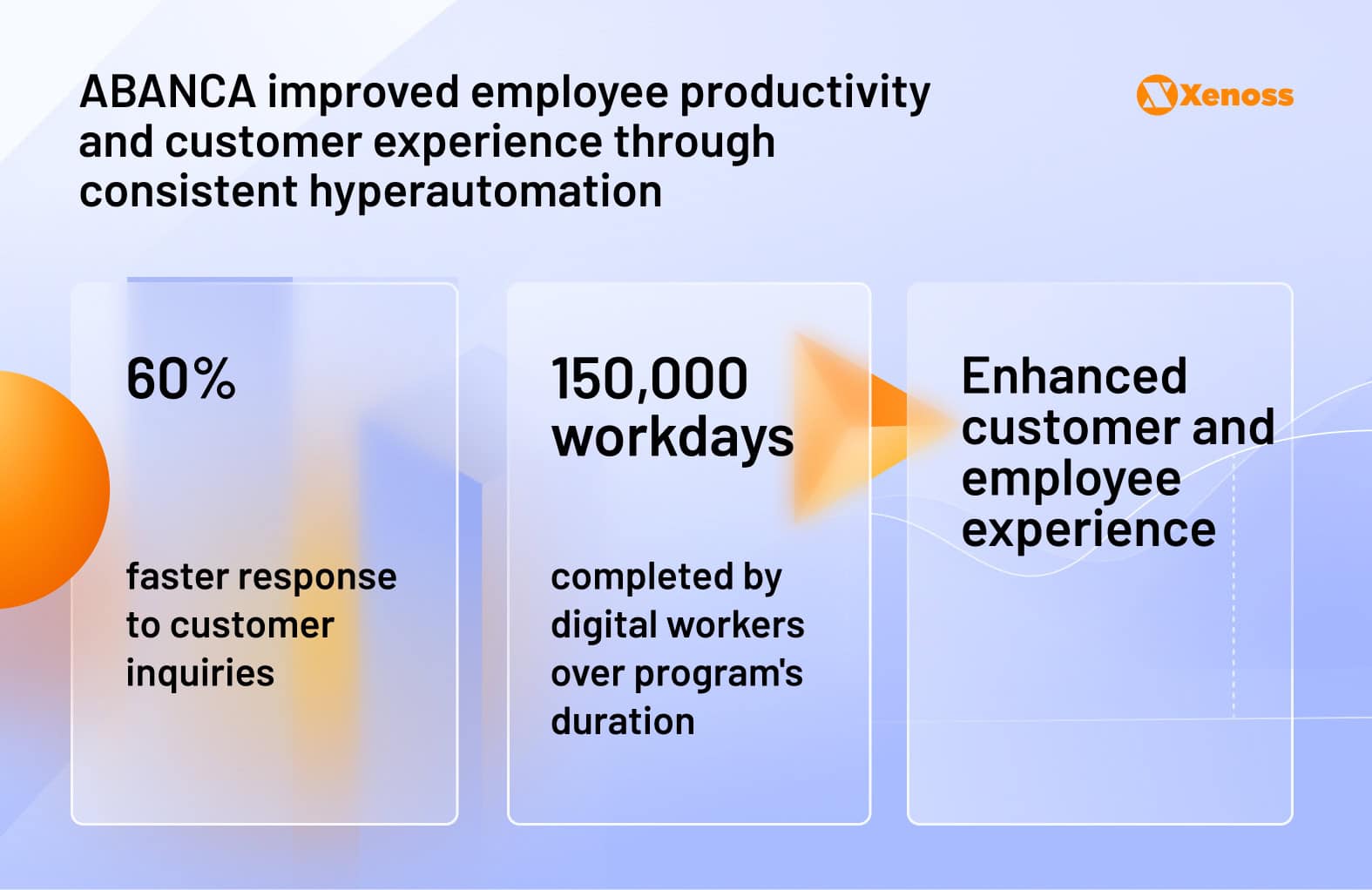

Lesson #1: ABANCA, a Spanish retail bank, approaches hyperautomation as a long-term commitment

ABANCA’s latest hyperautomation project, a solution combining generative AI, OCR, and robotic process automation to automate customer request handling, was an undeniable success.

The automated system has now completed the amount of document processing that would take human teams 150,000 workdays. ABANCA’s customers also saw better service, with 60% faster response to document inquiries.

Did ABANCA just happen to ‘stumble upon’ the right workflow to automate and choose just the right technologies for the job? Not at all. The bank’s digital transformation track record is impressive: 8 years of building automation pilots for over 1,000 tasks.

Over the years, the company built an internal automation system. ABANCA has trained over 150 employees to create automations and manage intelligent systems in their departments.

It also carefully considered how to allocate resources that were freed by automation. Instead of attempting to replace human teams with AI-only workflows, they redirected skilled talent to more demanding yet fulfilling tasks: cross-selling and providing personalized customer service.

Takeaway: Successful hyperautomation is an ongoing commitment. CIOs should continue to train their skills in identifying workflows that would benefit from automation the most, create internal units to help expand and manage change, and upskill employees to build high-value customer interactions.

Lesson #2. Laying solid foundations brought Heineken reliable returns

When a company of Heineken’s size and impact (currently the brewer employs over 80,000 professionals) plans a hyperautomation pilot, the complexity will escalate fast.

The company’s global hyperautomation product manager Lucy Todorovska realized the importance of laying the foundations that would support hundreds of diverse use cases.

In 2019, the company built The Toolkit: a technology stack capable of powering robotic process automation, document processing, intelligent chatbots, low-code development, automated testing, and toolchains.

The mix of these technologies was then applied to automating over 140 processes in the organization across IT, procurement, HR, commerce, and back office.

Another intelligent decision for Heineken’s product teams was realizing that a single centralized hyperautomation unit would struggle to implement this ambitious roadmap across multiple regions.

A federated system, where each regional office sets up a separate hyperautomation unit, was a more flexible solution that brought the brand powerful returns. Heineken now has 13 small federated teams (3-7 people) globally. These dedicated units help the brand promote new automations and save over 14.000 hours each month.

Takeaway: A successful hyperautomation pilot should rest on a reliable foundation.

technologies that will be part of the tech stack, and a model to scale innovation across departments and regional offices help eliminate friction and confusion down the road.

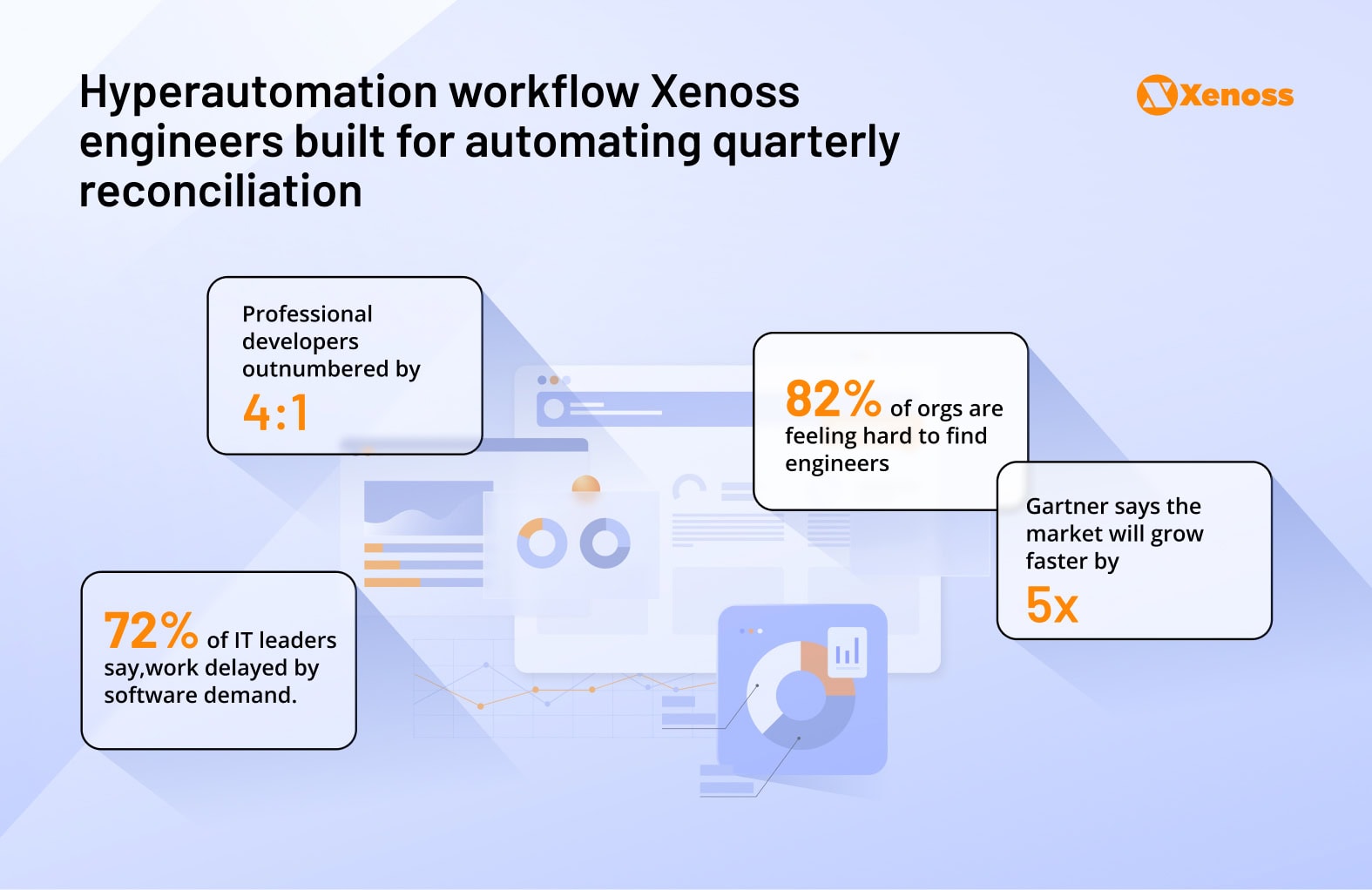

Lesson #3. Mitsubishi Tanabe Pharma tapped into citizen development to scale hyperautomation

The generative AI boom created a whole generation of ‘vibe-coding’ tools that give non-engineers room for building functional applications.

These platforms address the problem of tech talent shortage at large enterprises. Gartner estimates that citizen developers will outnumber professional engineers at large companies by 4:1.

People with no formal education in computer science are expected to ship up to 70% of enterprise applications in the next five years.

Citizen developers are becoming the driving force behind hyperautomation if organization leaders have created the environment that fosters and rewards innovation.

Mitsubishi Tanabe Pharma, one of the largest Japanese pharmaceutical companies, established a citizen developer culture that enabled the automation of over 400 workflows, resulting in savings of more than 48,000 working hours across multiple departments.

The company set up an internal center of excellence that consolidates all automations, including pharma research, accounting, general management, and HR. This unit also oversees no-code development initiatives across the company and encourages staff to build ‘self-driven’ automations for specific tasks.

The goal is to develop a wide range of citizen developers, including those who can develop workflows and determine which operations are suitable for automation.

Mitsubishi Tanabe Pharma spokesperson

Takeaway: Hyperautomation should not be seen as an engineering-only task. Giving other departments tools to directly automate specific workflows helps find high-yield automation use cases and spread innovation across the team.

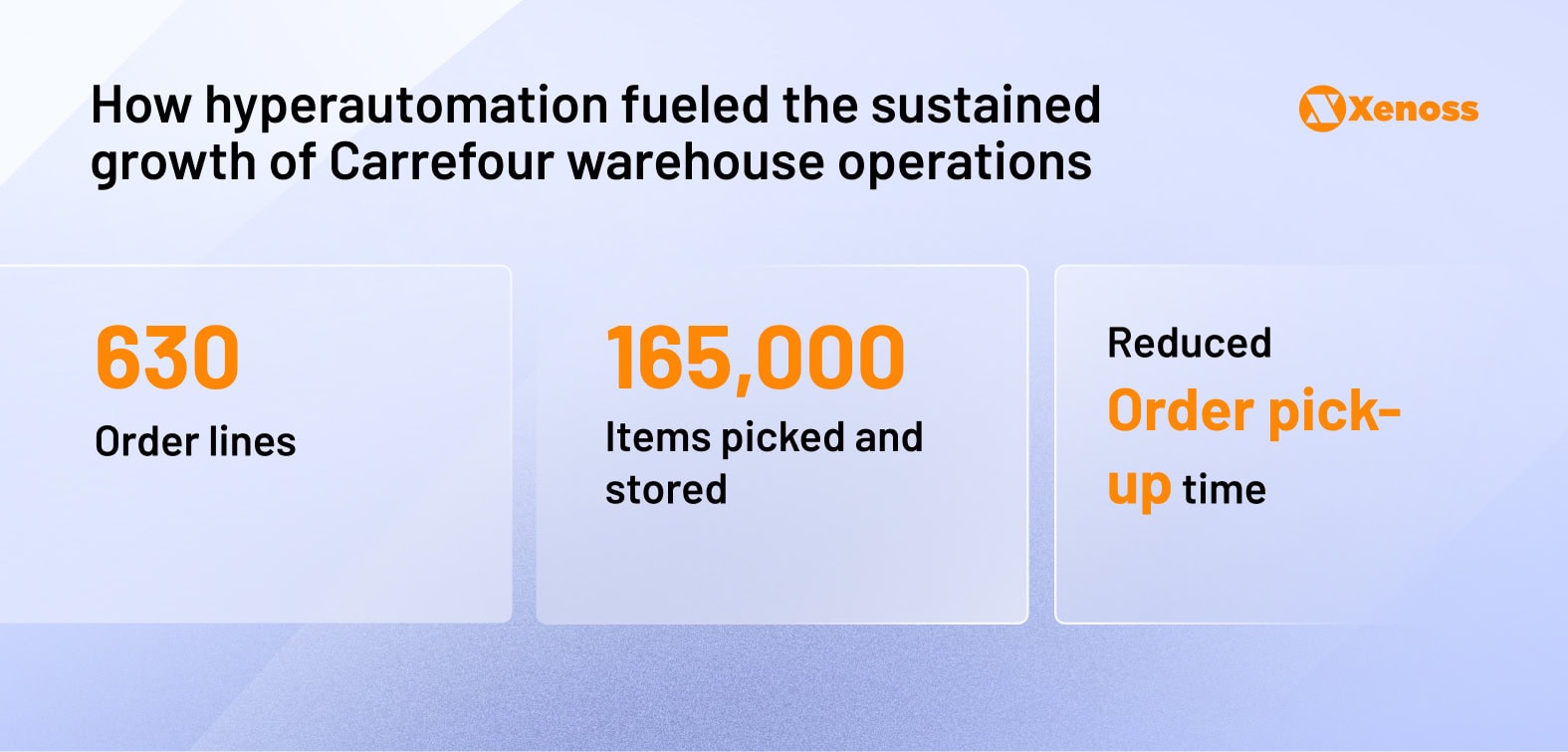

Lesson #4: Building with growth in mind helps Carrefour continue picking up speed

Executives often consider hyperautomation as a way to reduce high operational costs or solve performance bottlenecks. When there are no significant customer service delays or talent shortages, automating workflows might seem like a problem for another day.

But if executives start planning for the challenges they will encounter during consistent growth, that’s when they can get the most out of market tailwinds.

Carrefour showed this approach by anticipating the rapid growth of its warehouse needs. The company’s leadership predicted that a micro-fulfillment center in Reimes would be too difficult to manage manually, given the company’s growth rate.

Carrefour realized that automating manual workflows is necessary if the brand wants to keep high customer satisfaction and protect its reputation for accurate picking.

To make sure the company’s small software could manage over 165,000 items, Carrefour installed an intelligent picking system that orchestrated automated picking by combining robotics and smart software.

Now Carrefour manages over 630 order lines in a warehouse smaller than a high-school gymnasium. Order preparation and picking also helped the retailer drastically cut pickup times.

Takeaway: Estimating the pace of your organization’s growth and starting hyperautomation before it becomes essential helps companies adjust to increasing operational load and keep customer satisfaction even as back-office complexity increases.

Pitfalls that stall enterprise hyperautomation pilots

Successful hyperautomation initiatives are powerful time-saving and cost-saving strategies, but they’re not silver bullets for internal bottlenecks.

It is the other way around: the failure to build a system for hyperautomation, poor understanding of the tools teams are using to automate workflows, and brittle infrastructure to empower these projects can turn automation into a new fire for engineering teams to put out.

Let’s look into three cases of teams having to handle major enterprise hyperautomation challenges and the solutions they found to these problems.

Pitfall #1. Emerson’s hyperautomation project missed SLAs because of integration mishaps

Hyperautomation integrates multiple technologies in a single patchwork where different solution types and engineering tools interact seamlessly to monitor the status of each pipeline component and have access to up-to-date data.

Unfortunately, integration mismatches can appear when the pilot is already underway or complete, forcing teams to look for workarounds and ultimately not meeting expectations.

This happened to Emerson, one of the early adopters of industrial hyperautomation. The company’s first automation vendor lacked the connectors needed to integrate automatic workflows with the company’s Oracle ERP. Developers tried to solve the problem manually by writing custom Python code and embedding it into bots.

That system was still imperfect and caused processing delays, which Emerson engineers tried to mitigate by connecting a third-party bot scheduling platform.

Had the team chosen an open-source RPA solution instead of a proprietary solution with a limited number of connectors, they would not have faced this problem.

Takeaway: Consider which tools in your hyperautomation pipeline need to communicate with each other and ensure there are plug-and-play integrations connecting solutions. Alternatively, choosing open-source platforms for hyperautomation or building custom tools gives engineering teams the freedom to design integrations on demand.

Pitfall #2. Brittle automation technology required O2 Telefonica to hire four full-time employees to monitor bots

CIOs focus a lot on finding a hyperautomation use case that would deliver value. However, even if you discovered a workflow that is highly attuned to automation, the value of the pilot can still be disrupted if the underlying tech is not resilient enough.

O2 Telefonica originally started with an RPA-only platform to automate customer service. The pilot quickly spread across the organization, until automated bots were handling over 20,000 interactions per day.

However, managing bots became challenging due to regular system failures and the need to swap robots to prioritize transactions based on their SLAs manually. At one point, Telefonica O2 employed four full-time bot managers to monitor the pipeline and avoid downtime.

We had four employees providing full-time coverage of tasks that should have been automated, such as monitoring, scheduling, and prioritization, in case of process failure. This was a waste of resources from a commercial perspective, as these team members could have been focusing on other value-driving tasks.

Klaus Paul, O2 Telefonica

To solve this problem, the company made two impactful changes:

- Deployed an AI-powered orchestrator that monitored bots 24/7 and automatically resolved simpler (L1- and L2-level) failures.

- Tested and improved the resilience of the underlying tech stack to make sure bots did not break as often.

These tweaks increased efficiency fivefold, allowing O2 Telefonica to process over 100,000 daily interactions. Before the automation program, the company used to handle around 300,000 queue items per month – now it is processing over 1.4 million requests.

Takeaway: Finding a high-yield hyperautomation use case matters, but so does resilient tech. Having to spend a lot of time maintaining bots defies the very purpose of hyperautomation, so focus on resilience and automated orchestration from Day 1.

Pitfall #3. High infrastructure costs due to poor resource management

Not looking under the hood of your hyperautomation pilot can keep your team from unlocking added value. Newell, an industrial manufacturer, was seeing moderate success with hyperautomation, but a closer infrastructure inspection revealed that, despite fully saturating servers, the company was not maximizing the impact of the tools they developed.

Newell was relying on a proprietary solution with a single-threaded architecture, meaning only one automation could run at a time.

We were getting to the point where, as we wanted to add more processes to our environment, it was becoming increasingly difficult for us to fit them in because of how many processes we had running on our three servers. This meant that it sometimes took us longer to implement processes or get something deployed.

Mark Robinson, Newell hyperautomation case study

On top of that, employees struggled to identify the right tasks for automation and would often streamline low-yield opportunities.

Newell solved this problem by introducing a quality assurance system that determined whether a process was fit to be included in the hyperautomation pilot. The processes that qualified were then scheduled for execution via an AI-enabled scheduler.

Takeaway: Before assuming that there’s no room for increasing the value of your hyperautomation pilot, carefully assess its under-the-hood infrastructure. You may discover avenues for cost optimization and unlock ways to streamline more tasks simultaneously without increasing TCO or downtime.

Bottom line

Hyperautomation, fueled by a mix of innovative technologies, scales workflow automation at a pace that was previously inaccessible. A combination of RPA, IoT, and generative AI can be game-changing in streamlining HR, IT, marketing, sales, and back-office operations.

However, hyperautomation is not a ‘quick fix’ for all operational bottlenecks. Successful hyperautomation pilots are usually preceded by years of thoughtful experimentation, careful planning, and a deep understanding of the company’s processes.

The most successful implementations share common characteristics: they start with automation-friendly processes, build on solid technological foundations, leverage citizen development to scale innovation, and plan proactively for growth rather than reactively to problems.

Meanwhile, the most common failure patterns are predictable: integration mishaps between incompatible systems, brittle technology requiring constant manual intervention, and poor resource management that wastes infrastructure investments.

A measured and balanced approach to hyperautomation helps teams avoid the ‘build now, fix later’ mindset bound to create bottlenecks and high maintenance costs in the long run, or automate wrong processes in the first place.

For CIOs evaluating hyperautomation initiatives, the question isn’t whether to automate, but how to build the organizational capability to automate effectively and sustainably at scale.